Assemble millions of microLEDs with sub-micron placement accuracy

Our Photo-Polymer makes it Possible

Why MicroLEDs?

MicroLEDs are widely considered the Future of Display Technology. Displays built with MicroLEDs offer many advantages over OLED, today’s state of the art. Imagine a display that is:

- Ultra-high resolution (~10x OLED)

- Low power (50% less than OLED)

- Perfect black + Higher brightness

- No image retention

- Environmentally stable

- Wide viewing angles

- Curved / flexible

- Transparent

Application: Automotive

Automotive applications are a target use case for MicroLED displays. Their high brightness makes them ideal for daylight visibility, and displays can be built to match the contours of a curved console. Since only about 10% of the display surface area needs to be populated with light emitters, there is plenty of room left for embedded environmental and touch sensors.

At ambient temperatures of 60-70 degrees, the temperature inside a car can reach over 110 degrees. Since MicroLEDs are non-organic, they are stable over a much wider temperature range than OLED, and will retain their high brightness and contrast over the lifetime of the vehicle.

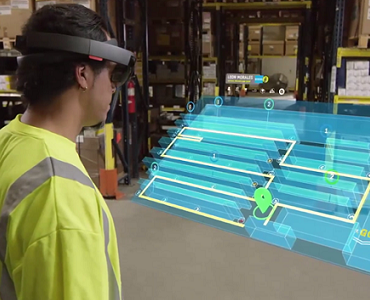

Application: AR/VR

MicroLEDs are the enabling technology for the near-eye displays required to make the next generation of AR/VR devices. Besides the improvement in video quality over OLED, lower power means smaller batteries and a lighter headset that can be worn for extended periods of time.

For Augmented Reality (AR), MicroLED displays provide the combination of transparency (necessary to simultaneously view the projected image and the physical environment) and high brightness (necessary to overcome ambient full-sun light outdoors).

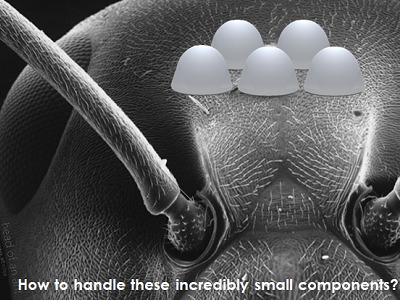

The Challenge: MicroLEDs are Incredibly Small!

MicroLEDs are called “Micro” for a reason; they can be as small as 5-50 microns, smaller than a grain of pollen. For comparison, a human hair is 80 microns in diameter.

Size matters – current factories cannot build these products at volume. A MicroLED TV has about 35 Million of these tiny components. Building a display requires transferring thousands of MicroLEDs from wafers to substrates and placing them with sub-micron accuracy.

Using current tools, an Automotive Console would take 3 days to assemble, an AR/VR headset 33 days, and a 4k 80″ TV would take 58 days!

Our Solution - Photo-polymer Mass Transfer

MicroLED panel assembly requires a way to both (a) pick up and transfer 1000’s of components simultaneously to achieve speed; and (b) place them in tight RGB clusters at a selectable horizontal and vertical offsets to achieve the desired final pitch of the pixels and deliver full color.

Terecircuits achieves this by using individual donor plates to pick up the different colored MicroLEDs directly from singulated wafers. These MicroLEDs are held on the donor plate at the fabrication pitch, but through use of an opaque mask designed to match the pixel pitch, only 10% of the LEDs will be selectively released to the display substrate when activated by light.

A simple realignment of the mask and repositioning over a new section of the display substrate will release the next 10% of MicroLEDs, and so forth until the entire wafer of MicroLEDs has been distributed and placed in pixel groupings at the correct pitch.